Mechanical engineering

Description

Ensure conformity of the technical product and optimize its components for production.

Mechanical engineering and design

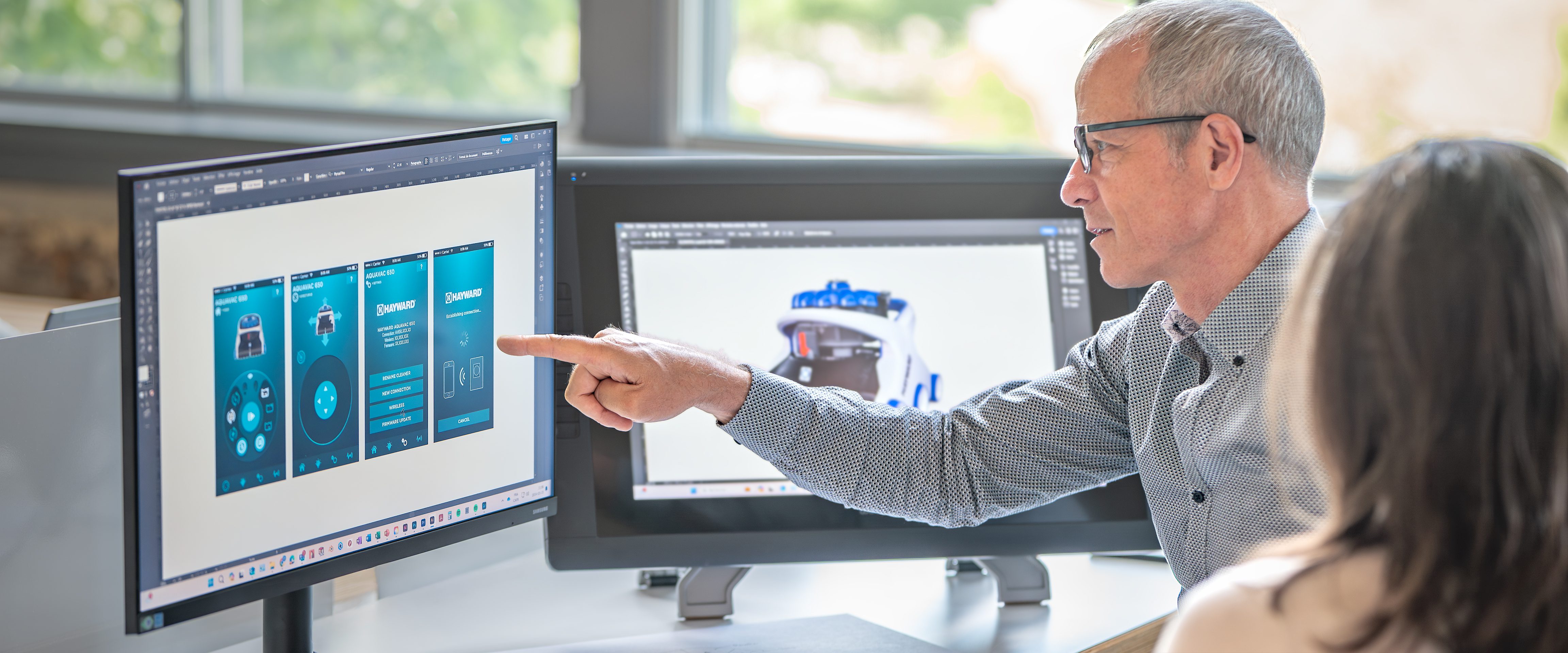

Our multidisciplinary team works closely together to ensure the manufacturability of design concepts

Imagining products is one thing, but making sure they can be mass-produced is another story. At Alto, technical development is handled by a team of engineers and mechanical designers. They work to optimize the design of parts to meet production and manufacturing requirements, while respecting the original design intent. Rigorous management of part and drawing revisions is ensured thanks to the PDM vault administered by our engineering team.

To accomplish this task, they can rely on several tools:

- Complex 3D and surface modeling

- File lifecycle management with PDM vault

- Finite element analysis (FEA)

- Risk analysis

- Optimization for manufacturing and assembly processes (DFM/DFA)

- Geometric dimensioning and tolerancing (GD&T)

- Manufacturing and assembly drawings, bill of materials (BOM)

- Physical testing

- Part inspection (FAI)

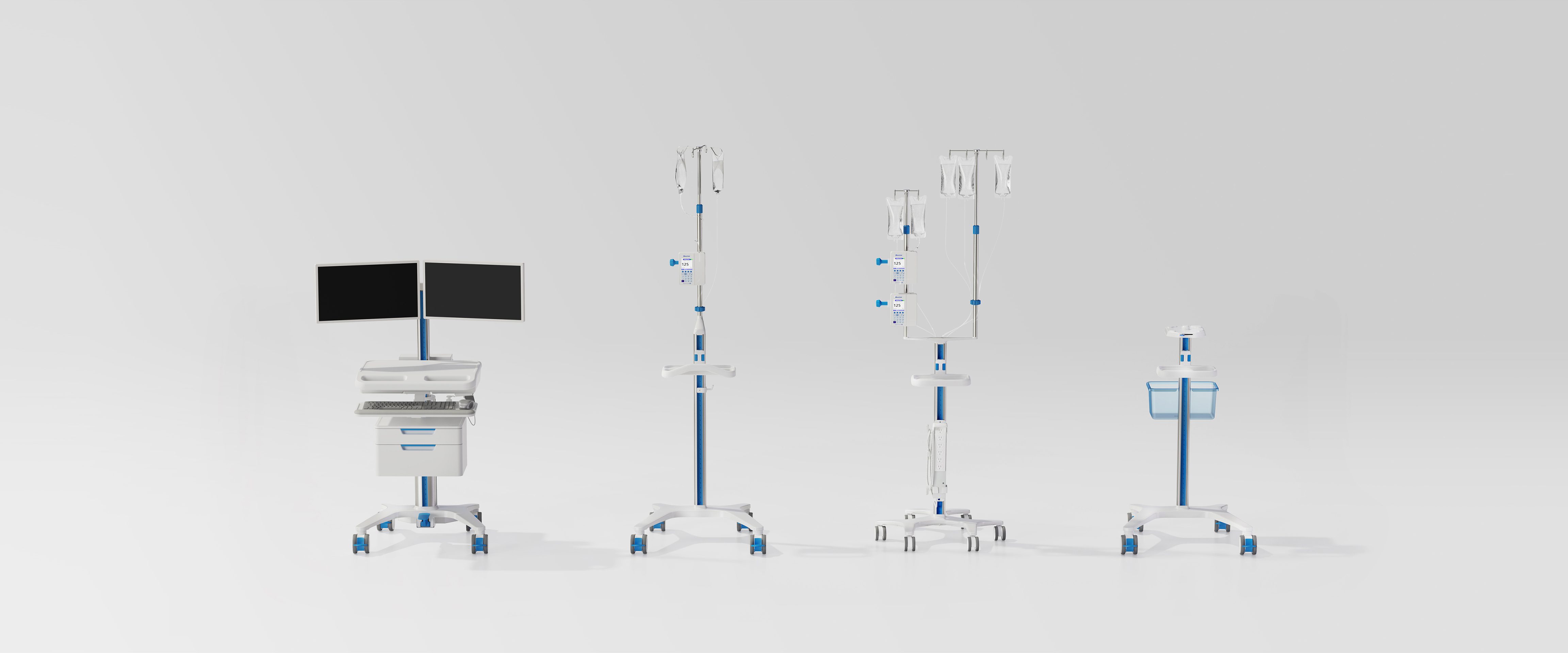

Mechanical design

During the refinement of selected concepts, our mechanical engineering and design teams optimize products for production, ensuring the manufacturability of components relative to their manufacturing processes. Depending on your requirements, we select the best-performing materials and carry out manufacturing and assembly optimization analysis (DFM and DFA). Backed by our extensive expertise in plastic injection molding, we ensure that your parts can be molded easily and retain maximum strength.

Our designers are skilled in 3D modeling of complex surfaces, enabling them to fine-tune parts surfaces and split lines as well as assembly specifications. They can also design complex mechanisms, taking into account dimensional and physical constraints.

Committed to quality, we ensure the delivery of complete manufacturing documentation, with meticulous implementation of tolerancing analysis and GD&T principles to ensure product conformity.

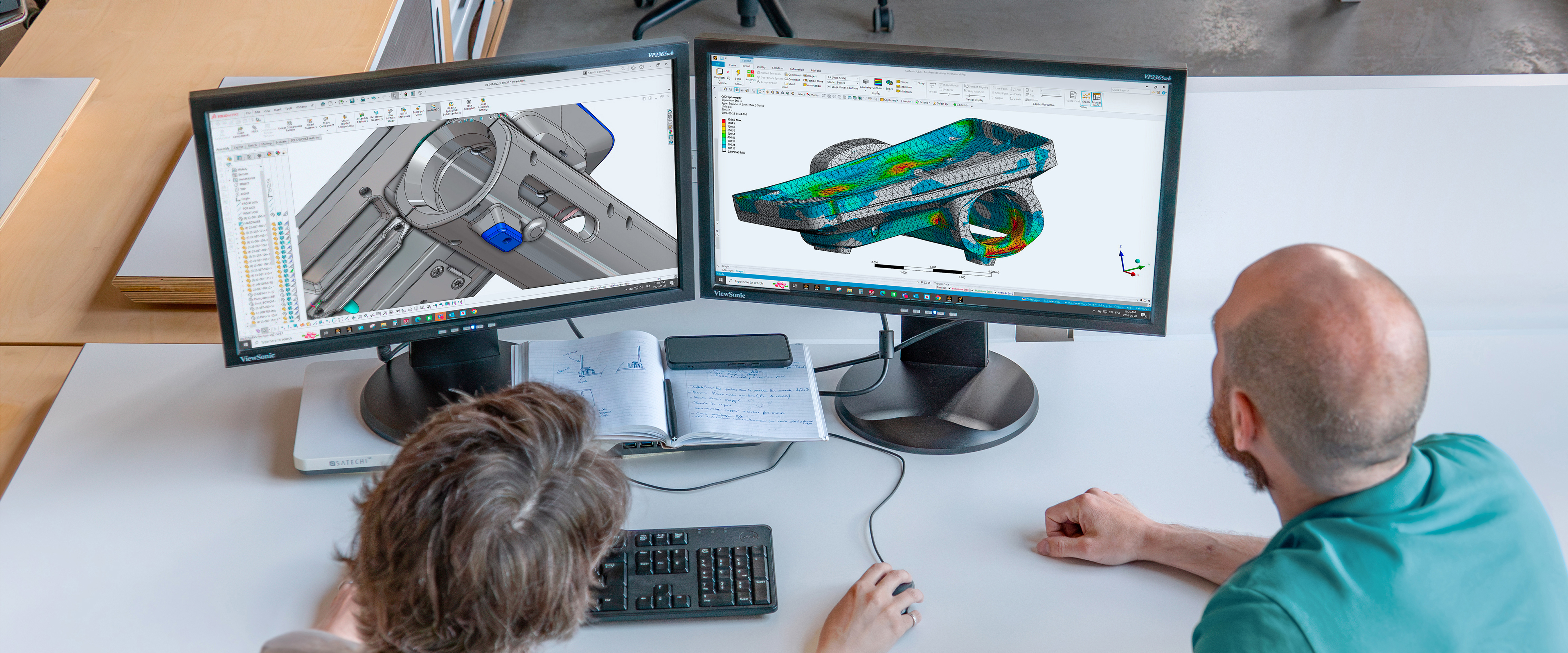

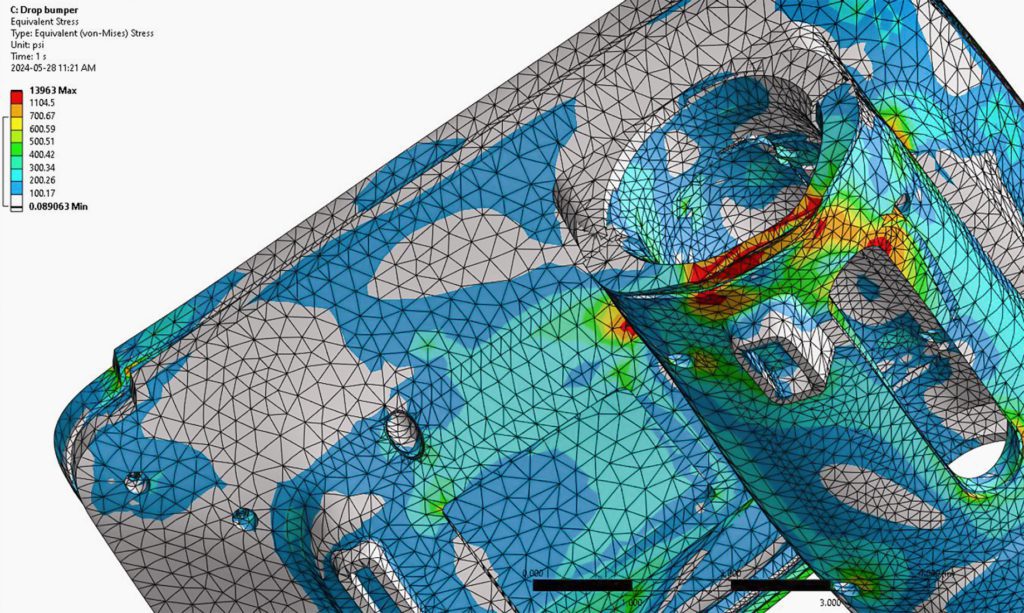

Finite element analysis (FEA)

We use advanced finite element analysis (FEA) techniques for static and buckling tests, which enable us to optimize our designs according to materials and manufacturing processes. These assessments contribute to product robustness and durability, while ensuring compliance with the most stringent safety standards. The result is a significant improvement in structural performance, enabling materials optimization and increased durability.

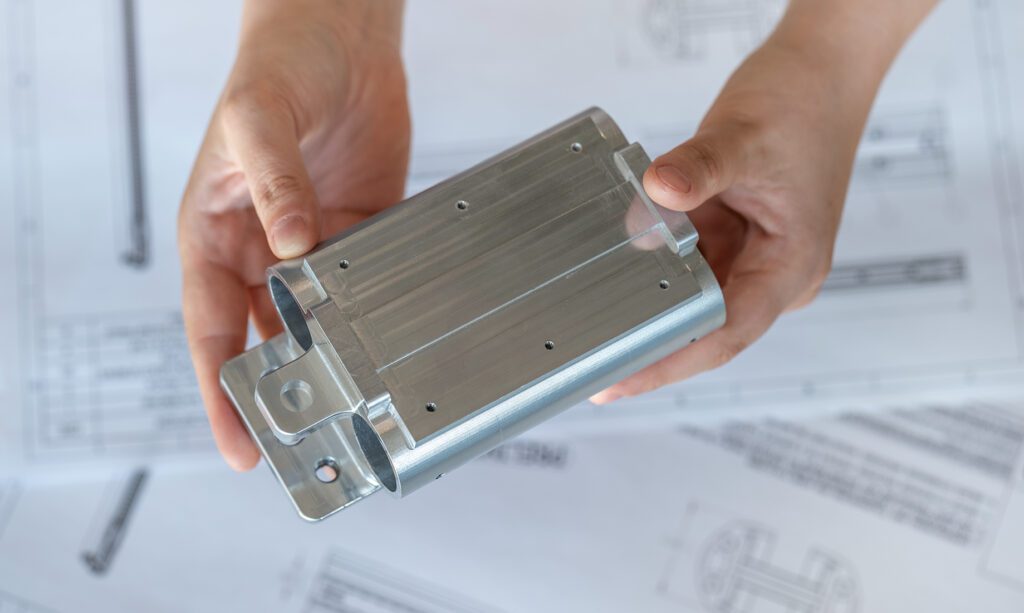

Tests

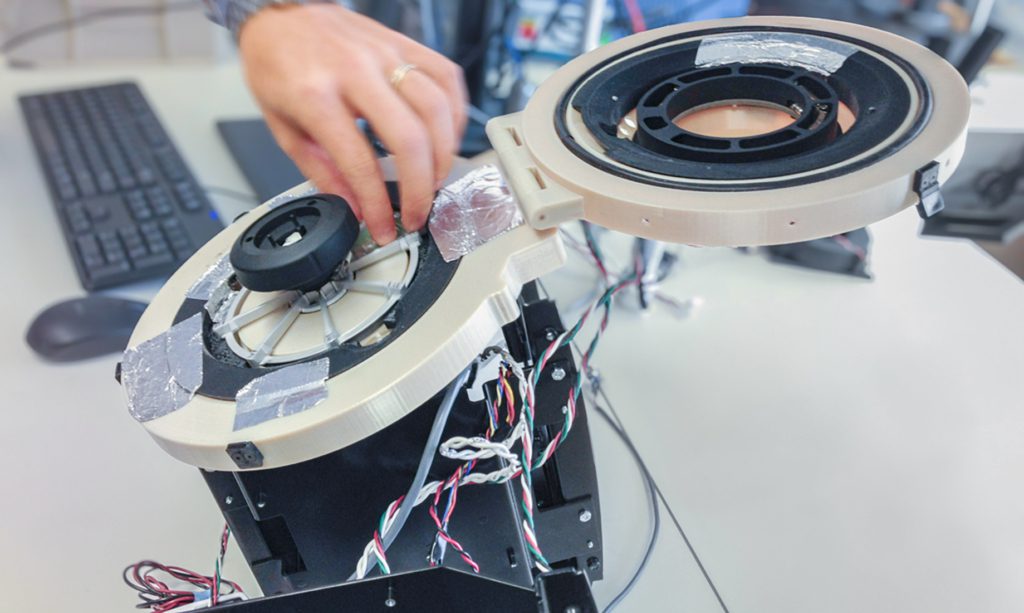

Performing physical tests at various points in the design process speeds project development and enables quick verification of functional requirements before submitting the product to certified laboratory tests.

Our mechanical engineers can help you develop test plans, rigorously detailing lists of requirements. Our multi-technical workshop also enables us to design specific test benches to support your internal verification processes. We carry out a wide range of pre-verification tests on our own premises, including load, leak and duty cycle tests.

Ensure the conformity and optimization of your products with the engineering and mechanical design services of our experienced team. Tell us about your needs today!